Bahan Konstruksi Gulungan Baja Galvanis Celup Panas Berkualitas Tinggi z275

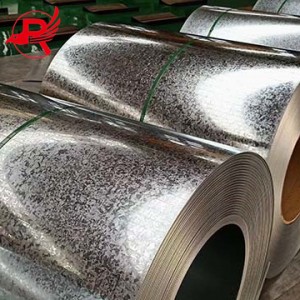

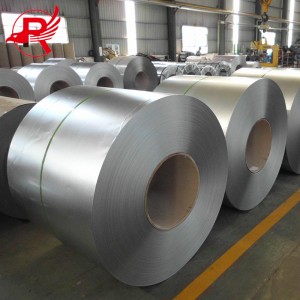

Kumparan galvanisLembaran baja tipis yang dicelupkan ke dalam bak seng cair agar permukaannya menempel pada lapisan seng. Saat ini, lembaran baja ini terutama diproduksi dengan proses galvanisasi kontinu, yaitu pelat baja gulung terus menerus dicelupkan ke dalam bak berisi seng cair untuk membuat pelat baja galvanis; Lembaran baja galvanis paduan. Jenis pelat baja ini juga dibuat dengan metode celup panas, tetapi dipanaskan hingga sekitar 500 ℃ segera setelah dikeluarkan dari tangki, sehingga dapat membentuk lapisan paduan seng dan besi. Kumparan galvanis ini memiliki kekedapan lapisan dan kemampuan pengelasan yang baik. Kumparan galvanis dapat dibagi menjadi kumparan galvanis canai panas dan kumparan galvanis canai dingin.Gulungan Baja Galvanisyang terutama digunakan dalam konstruksi, peralatan rumah tangga, otomotif, kontainer, transportasi, dan industri rumah tangga. Secara khusus, konstruksi struktur baja, manufaktur otomotif, manufaktur gudang baja, dan industri lainnya. Permintaan industri konstruksi dan industri ringan merupakan pasar utama gulungan galvanis, yang mencakup sekitar 30% dari permintaan lembaran galvanis.

Kumparan galvanis adalah jenis material logam yang dilapisi seng pada permukaan kumparan baja dan memiliki banyak karakteristik. Pertama, kumparan galvanis memiliki ketahanan korosi yang sangat baik, melalui perlakuan galvanis, permukaan kumparan baja membentuk lapisan seng yang seragam, secara efektif mencegah korosi baja oleh atmosfer, air, dan zat kimia, sehingga memperpanjang masa pakainya. Kedua, kumparan galvanis memiliki kekuatan dan kekerasan yang tinggi, sehingga dapat menahan tekanan dan beban tertentu selama penggunaan. Selain itu, kumparan galvanis juga memiliki sifat pengolahan dan dekoratif yang baik, cocok untuk berbagai pengolahan dan perawatan permukaan, sekaligus memberikan tampilan yang indah. Karena karakteristik ini, kumparan galvanis banyak digunakan dalam konstruksi, furnitur, manufaktur otomotif, peralatan tenaga listrik, dan bidang lainnya, merupakan material logam penting, yang berperan penting dalam melindungi baja dari korosi dan memperpanjang masa pakainya.

Produk gulungan baja galvanis terutama digunakan dalam konstruksi, industri ringan, otomotif, pertanian, peternakan, perikanan, perdagangan, dan industri lainnya. Industri konstruksi terutama digunakan untuk pembuatan panel atap anti korosi dan kisi-kisi atap untuk bangunan industri dan sipil; dalam industri ringan, digunakan untuk pembuatan cangkang peralatan rumah tangga, cerobong asap sipil, peralatan dapur, dll. Dalam industri otomotif, terutama digunakan untuk pembuatan suku cadang mobil yang tahan korosi, dll; pertanian, peternakan, dan perikanan terutama digunakan sebagai penyimpanan dan pengangkutan makanan, alat pengolahan beku untuk daging dan produk perairan, dll; terutama digunakan untuk penyimpanan dan pengangkutan material dan alat pengemasan.

| Nama Produk | Gulungan baja galvanis |

| Gulungan baja galvanis | ASTM, EN, JIS, GB |

| Nilai | Dx51D, Dx52D, Dx53D, DX54D, S220GD, S250GD, S280GD, S350GD, S350GD, S550GD; SGCC, SGHC, SGCH, SGH340, SGH400, SGH440, SGH490, SGH540, SGCD1, SGCD2, SGCD3, SGC340, SGC340, SGC490, SGC570; SQ CR22 (230), SQ CR22 (255), SQ CR40 (275), SQ CR50 (340), SQ CR80(550), CQ, FS, DDS, EDDS, SQ CR33 (230), SQ CR37 (255), SQCR40 (275), SQ CR50 (340), SQ CR80 (550); atau Persyaratan Pelanggan |

| Ketebalan | Ukuran 0,10-2mm dapat disesuaikan sesuai kebutuhan Anda. |

| Lebar | 600mm-1500mm, sesuai kebutuhan pelanggan |

| Teknis | Kumparan Galvanis Celup Panas |

| Lapisan Seng | 30-275 g/m2 |

| Perawatan Permukaan | Pasivasi, Peminyakan, Penyegelan pernis, Fosfatasi, Tidak diolah |

| Permukaan | payet biasa, payet misi, cerah |

| Berat Kumparan | 2-15 ton metrik per gulungan |

| Kemasan | Kertas tahan air sebagai kemasan bagian dalam, lembaran baja galvanis atau baja berlapis sebagai kemasan bagian luar, pelat pelindung samping, kemudian dibungkus dengan tujuh sabuk baja.atau sesuai dengan kebutuhan pelanggan |

| Aplikasi | konstruksi struktur, kisi-kisi baja, peralatan |

T: Apakah Anda produsen?

A: Ya, kami adalah produsen. Kami memiliki pabrik sendiri yang berlokasi di Kota Tianjin, Tiongkok.

T: Bisakah saya melakukan pemesanan percobaan hanya beberapa ton?

A: Tentu saja. Kami dapat mengirimkan kargo untuk Anda dengan layanan LCL (Less Container Load).

T: Apakah sampelnya gratis?

A: Sampel gratis, tetapi pembeli menanggung biaya pengiriman.

T: Apakah Anda pemasok emas dan melakukan penjaminan perdagangan?

A: Kami adalah pemasok emas selama tujuh tahun dan menerima jaminan perdagangan.